[ Mycelium ]

Sustainable materials

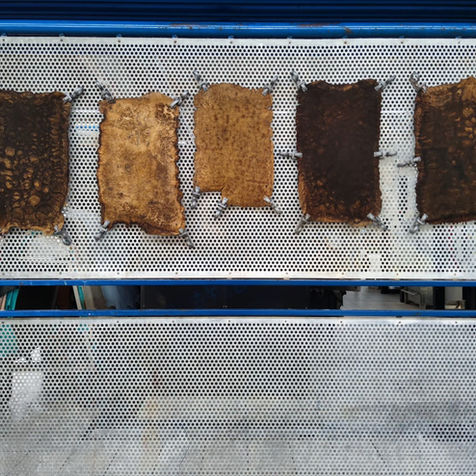

We evaluated, tested and co-built 10+ different base materials until we evaluated the right partner. It was all about scalability and price-parody vs simply a material sample that looks great.

We spent years in a tight collaboration, in the style of the venture studio, where the startup-corporate venture team-external customer, combined in a JDA to develop a system not a product for success.

We improved materials, developed chemical processes derived from the knowledge of leather making, but applied to mycelium's unique physical and biological properties.

But this alone would not provide success, so we had to think about what the factory of the future would look like. It's easy to throw money at a brand new factory, but our thoughts were different - with more than 50% of tanneries remaining unused or closing down, we didn't need to develop something brand new, but retrofit the 1000s of years of knowledge to apply to the new blank canvas that was mycelium.

Tanneries to us were not about leather, but about taking a natural base and creating a beautiful material from it.

So with some tweaking we were able to retrofit tanneries to preprocess more fragile fibers to undergo the same mechanical processes we have perfected for leather.

The outcome, a material that pushes price parody, was pushy near perfect biobased ingredients and that could return to natural. All this while being able to apply it to existing product categories.

We imagined products that would last seasons, not lifetimes, that could be composted in your garden after use, not thrown away.

A value chain where each material served a purpose in the right product, leather for longevity and strength, while mycelium for seasonality and circularity.

To us mycelium was not an alternative to leather - but rather a non-animal blank canvas for creation